Tracked skid steer loader TS100 is Multi-functional construction equipment, it is easy to control.it could be easily and quickly attached to various accessories to achieve various works. our tracked skid steer loader TS100 is widely used in gardens, manufacturing, construction sites, recycling, gardens, roads, Construction, farms and other industrial fields...with our skid steer loader superior quality,it will give you good performance.

TS100 | |

Rated capacity (kg) | 1200-1500 |

Max speed rate (km/h) | 12/18 |

Hydraulic flow rate (L/Min) | 140 |

Big flow rate | 140 |

Track size | 320X86/450X86 |

Engine power (Kw) | 74 |

Diesel oil tank volume (L) | 90 |

Operating weight (kg) | 4500 |

Bucket Volume (m³) | 0.55 |

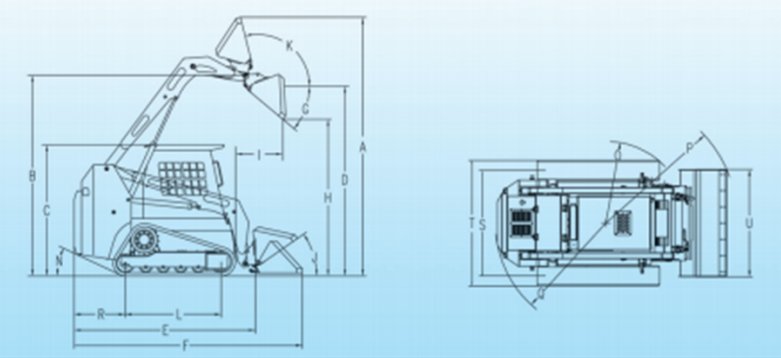

Model Technical parameter | TS100 | |

A | Overall operating height (mm) | 4070 |

B | Height to bucket hinge pin (mm) | 3280 |

C | height to top of cab (mm) | 2160 |

D | Height to bottom of level bucket(mm) | 3140 |

E | Without bucket length(mm) | 3000 |

F | overall length with bucket(mm) | 3700 |

G | Dumping angle at maximum height(°) | 40 |

H | Dumping height(mm) | 2500 |

I | Dumping reach(mm) | 700 |

J | Rollback o bucket on ground(°) | 30 |

K | Rollback of bucket at full height(°) | 104 |

L | Wheelbase(mm) | 1500 |

M | Ground clearance(mm) | 200 |

N | Angle of departure(°) | 20 |

O | Front turning radius without bucket(mm) | 1365 |

P | Front tuning radius(mm) | 2200 |

Q | Rear tuning radius(mm) | 1742 |

R | Rear axle to bumper (mm) | 938 |

S | Tread width (mm) | 1654 |

T | Width (mm) | 1994 |

U | Bucket width (mm) | 2030 |

1.Our design width is small and has good passability. The variable-width working arm ensures a strong bearing capacity in a small environment.

2. Hydraulic systems and pumps from Italy and the United States.

3. The control system adopts hydraulic pilot control, which is sensitive and responsive.

4. All important parts are produced by our company. We use high-quality national standard raw materials, real-time monitoring of every aspect of production, and re-inspection before assembly, to ensure that all parts are of good quality.

5. Excellent after-sales service, the company has sufficient spare parts to ensure that the required accessories are issued to customers within 24 hours. At the same time,

we have good engineers to provide after-sales guidance to the machine.

6. Quality product quality, exported to Europe and the United States, the machine has obtained European CE certification.

7. The machine production can be traced back. We strictly carry out production tracking records for each production process to ensure that the products have good traceability.

8. The device can be configured to use a variety of accessories, and the use of functions is greatly increased.

9. The machine is energy-saving and environmentally friendly, easy to operate.

10. Professional services to solve all technical problems before and after customer use, and help customers maximize revenue.